Original post from Food Navigator USA

In the next 12 to 18 months, cultivated meat could become available to the masses, according to some industry players raising funds to scale production of technological and scientific advances that will allow for lower production costs and a lower consumer price point.

Today, Israel-based Future Meat Technologies announced a significant price drop in the production of its chicken patties that beat investor expectations as well as a $26.75m fundraise that will allow it to further scale its GMO-free cell lines and bioreactors to further strive for price parity with conventional meat.

In addition, UK-based CellulaREvolution will announce this week a sizeable fundraise to support expansion of its bioreactor technology capable of serum-free continuous production of adherent cells – pushing it closer to its goal of bringing product to market in the next year.

Despite these investments and advances, industry players say more money is needed to help the cultivated meat (a.k.a. cell-based, cell-cultured) segment develop the equipment, cell culture mediums, scaffolding and cell-lines necessary to overcome hurdles in its way to capture a predicted 35% of the global meat market by 2040.

This episode of FoodNavigator-USA’s Soup-To-Nuts podcast looks at the rapid evolution of cultured meat and what it will take for the segment to overcome significant technological and scientific challenges to scaling and reach its full potential. Executives with Future Meat Technologies and CellulaREvolution, both of which participated in Rabobank’s FoodBytes! pitch competition in 2020, share how they are developing solutions to help finished product manufacturers ramp up production and bring down prices. In addition, a managing partner at Unovis Asset Management shares how the investment community is evaluating the space, an estimated timeline for development and where more money is need to bring cultivated meat to the masses.

‘We’re on the cusp of the deepest, fastest, most consequential disruption in food and agriculture’

The tide finally seems to be turning for cultivated meat, after years of facing derision and disbelief, scientific and technological challenges, and a desperate fundraising gap despite huge investments. Late last year, cultivated chicken appeared for the first time on restaurant menus in Israel and Singapore – not just as a novel item for the rich and famous – but as a viable, sustainable and ethical option for everyday people. At the same time, many industry players are advancing in leaps and bounds to bring more cultivated meat options to more people.

For Mark Langley, a managing partner with the alternative protein-focused investment group Unovis Asset Management, these developments are the fulfillment of a prophecy made more than a hundred years ago that promises even greater opportunity and returns in the coming years.

“We’re on the cusp of the deepest, fastest, most consequential disruption in food and agriculture production since we first domesticated plants and animals 10,000 years ago. This is a remarkable time to be in this field,” Langley said, noting that in 1894 a professor claimed people would manufacture meat by the year 2020.

“That was amazingly prophetic,” he said. ‘

He explained that in the 2000s meat cultivation first appeared in labs, but that “the genie really came out of the bottle” in 2014 with the founding of New Harvest, a donor-funded research institute focused on advancing the science behind cultured meat, milk and eggs from cells rather than animals.

Langley notes that now about 80 companies play in the alternative protein space with more than 40 focused on cultivated meat – a ratio he sees as promising, even if he says it is too early to know the real size of the prize.

Even without a clear picture of cultivated meat’s full market potential, Langley and other investors have eagerly poured billions of dollars into the segment, including $60m in cell-based seafood startup BlueNalu announced this month, which followed a $3.55m investment last year in UC Davis to investigate the long-term viability of cell-cultured meat, and a $7.4m investment in A Japanese cell cultured meat company to commercialise foie gras this year, and a whopping $161m in Memphis Meats to build a new cell-based platform, in addition to many other high-dollar deals.

While these amounts may raise eyebrows given cultured meat’s ambiguous payday and timeline, Langley says the investments are small compared to the potential returns and impact.

“This is an enormous change in the way we are producing foods, and I can’t underscore just how important this is and how little is being invested in this. … We can’t feed a planet of 10 billion people in 2050 the way we’re eating. Now this is one of the key solutions to that challenge,” he said.

Four main challenges

As passionate as Langley is, he isn’t naïve, and says he is going in with his eyes open to the challenges ahead for the industry.

“There’s four general science and technology challenges that need to be overcome to make this really a commercial reality, and those are cell lines, cell culture media, large-scale bioreactors and scaffolds,” each of which carries very different challenges, he said.

While these challenges are daunting, innovative companies are rapidly developing solutions. For example, Matrix Meats’ approach to scaffolding recently attracted Langley and others to invest in a deal announced this month.

CellulaREvolution raises £1m to support continuous cell production

In addition to scaffolding, for the cultivated meat industry to pull-off investor expectations it also will need large-scale, efficient bioreactors and effective, inexpensive media to produce sufficient cells at a price point that is palpable for consumers.

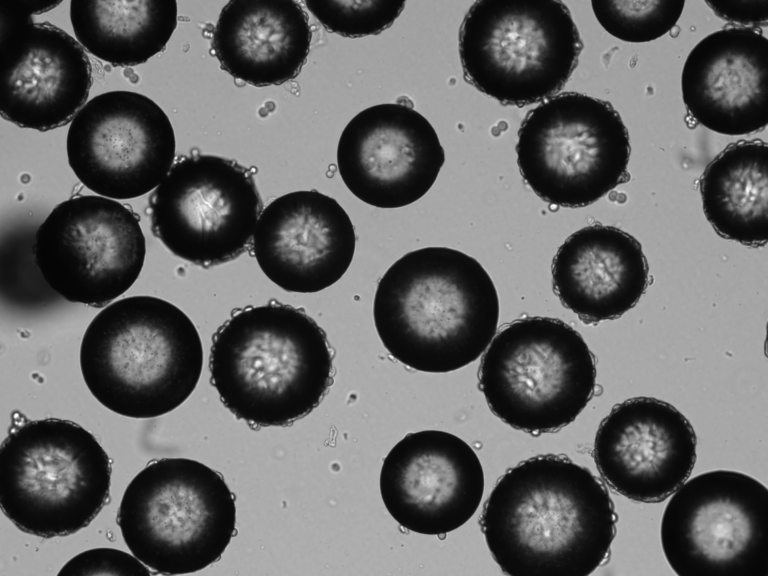

With the help of a recently closed £1m fundraise that will be announced this week, UK-based CellulaREvolution is rising to meet these challenges by creating a bioreactor capable of serum-free continuous production of adherent cells, which company cofounder and CEO Leo Groenewegen explains will help lower the cost of production and increase the yield so that finished product can more quickly find its way to mainstream consumers’ plates.

“We have developed proprietary technology that actually allows for an entirely novel type of way that cells are cultured and grown,” Groenewegen said, explaining that most cells are produced in batches but his technology allows for continuous production that mimics nature.

The cost savings of this technology will vary by cell line and company goals, but in a test run Groenewegen said the companies bioreactor, which was six times smaller than the competitor produced twice the yield.

“You’re looking at quite a big impact,” he said.

In addition, because the bioreactor is smaller, it needs less media and other inputs, which will also contribute to cost savings, he said.

A key component of CellulaREvolution’s more efficient bioreactors are novel peptide coatings that it created to automate production and increase cell proliferation. These also address another of the four key challenges laid out by Langley, which is efficient and cost-effective media.

The investors behind the £1m fundraise that CellulaREvolution will announce this week also will connect the company with other portfolio players that could be customers – creating a potentially robust business pipeline.

Future Meat Technologies slashes price for cultured chicken

Like CellulaREvolution, Israel-based Future Meat Technologies sees cultivated meat as a solution to feed the masses, which is why it has prioritized reducing the cost of its cultured chicken breast to $7.50 per patty by developing a line of GMO-free animal cells that grow indefinitely without animal-derived components and cost-effective, sustainable bioreactors.

The company’s announcement today that it has lowered the production cost of its cultured chicken breast to single-digits while maintaining the same texture and aroma of farm-raised chicken beat market expectation. The advances that made this possible also likely helped it raise an additional $26.7m in funding, which will help it scale production to bring its product to consumers within 18 months.

Future Meat Technologies CEO Rom Kshuk explains creating cost parity for cultivated meat compared to that from animals is extremely difficult because most animal agriculture is subsidized by the government, which he argues has artificially lowered the price point from consumers. But, he adds, cost parity is essential for consumer adoption and for cultivate meat to deliver on its promised environmental and nutritional impact.

“We need to get to a point that consumers would say, okay, I’m willing to pay that. And it’s not only a first try, but I’m willing to pay that in repeat purchase to see significant sale rates so that the produce would deliver on the promise and people would be willing to pay for it,” he said.

‘It’s getting there, it’s getting closer’

While creating a chicken breast to sell for $7.50 is ahead of the competition, Kshuk acknowledges the industry needs to drive down the price even more.

“I completely understand that $8 per patty is super premium, and even $5 per patty is super premium, but it’s getting there, it’s getting closer,” he said.

He explained that Future Meat Technologies was able to reduce the cost of culturing cells by first selecting efficient cell lines, second by optimizing their “feeding regime,” and finally by blending cultured meat with plant-based ingredients.

While whole-cut pieces are often touted as the holy grail of cultivated meat, Kshuk argues the industry must also focus on other more accessible forms for the masses, such as chicken nuggets, ground burgers, kebabs and sausages.

He also notes that companies must educate consumers on the benefits and legitimacy of cultured meat, because making accessible products will do no good if mainstream shoppers are frightened or distrustful of the technology behind them.

A long road ahead

Despite the leaps and bounds each of these companies – and the industry as a whole – have made, the cultured meat space still has a long ways to go and to get there, CellulaREvolution’s Groenewegen argues it will need more investment – especially in the B2B companies that support manufacturers of finished products.

“Many companies in the B2C space have raised considerable amounts of money, and that’s extremely good for the space. But what you’ll see is investments into the eco-system – the sticks and shovels companies – are also extremely important in order to … really push the capabilities and the developments of the industry further,” he said.

As such, he urged, “it’s really important to have also some of the investments into the B2B business in order to make sure that actually the B2C companies can deliver on what their promise is.”