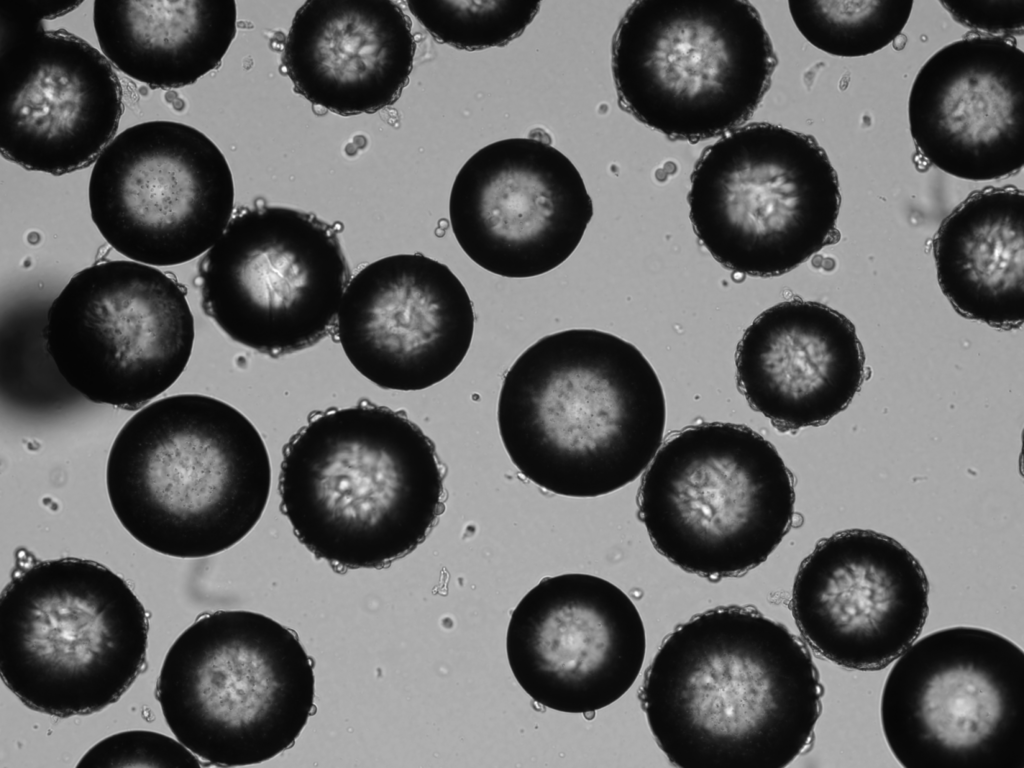

Multiple industries struggle to scale adherent cell culture for applications where the cells themselves are the target product. Traditional methods like T-flasks and multilayers, while useful in research settings, become limiting factors for large-scale production. Microcarrier-based cultures are a popular approach with many advantages, such as their high surface area per volume ratio, scalability, versatility, and integration with existing systems.

A typical microcarrier bioprocess follows a three-step progression. First, a microcarrier biocompatibility screen identifies suitable microcarriers for the specific cell type being cultured. This is followed by a scale-up to larger culture vessels, like spinner flasks. This step allows for the identification of a robust combination of appropriate media, operational conditions and, if required, improved microcarrier pairing (Chang & Wang, 2010; Meng, et al., 2017). Finally, the process is transitioned from spinner flasks to stirred-tank bioreactors. This step requires careful consideration of various technical aspects to ensure efficient cell growth and product yield. These technical considerations are discussed below.

1. Spinner Flask vs Stirred Tank Reactor: Hydrodynamics

Flat surfaces and spinner flasks play a crucial role in the early stages of microcarrier bioprocess development. However, even when these early steps are carried out excellently, a successful scale-up to a stirred tank reactor presents a distinct challenge. Spinner flask hydrodynamics differ significantly to a stirred tank reactor, which poses significant problems:

- Spinner flasks typically use large impellers that efficiently mix a high volume of culture at low rates per minute (RPMs). In contrast, stirred tank reactor often have smaller impellers relative to the culture volume, necessitating higher RPMs for adequate mixing. This difference in mixing profiles can be problematic.

- A weak cell-microcarrier pairing might initially succeed in a spinner flask, but it may struggle in the more turbulent environment of a stirred tank reactor (Derakhti, et al., 2019). Therefore, thorough optimisation of the cell-microcarriers pairing is crucial for a smooth transition to large-scale cultivation.

2. Seeding Approaches

Favourable biocompatibility might allow some microcarrier-cell combinations to reach the stirred-tank reactor, even if they display weaker cell attachment. Here are some practical strategies that can improve seeding efficiency, especially for these more difficult pairings.

a) Increase microcarrier-to-media ratio:

Increasing the microcarrier density statistically increases cell-to-microcarrier contact (Martin, et al., 2017). Additionally, a reduced media volume will increase oxygen transfer by increasing the surface area: volume ratio, this effect is complemented by increased surface agitation from the impeller. Improved oxygen availability is crucial for an intensified processes where oxygen consumption is high. Stirred tank systems may require sparging without this strategy, with aeration kept at a minimum during seeding to prevent cell damage. Post cell attachment, media volume is adjusted to the desired process volume.

b) Continuous stirring for optimal distribution:

Continuous stirring is preferred to facilitate even cell distribution on microcarriers (Ng, et al., 1996), especially for consistent, repeatable results. This approach is commonly used at CellRev for most cell types. However, continuous shear forces can reduce seeding efficiency, which can be countered by using a higher initial cell number. For weak cell-microcarrier pairings, continuous stirring might be ineffective altogether.

c) Intermittent stirring for low-adhesion cells:

Intermittent stirring may be more appropriate for shear sensitive cell types. A typical recommended intermittent stirring protocol will be active mixing for 5 minutes followed by no mixing for 30 minutes, up to a total of 6 hours. This allows cells to attach without constant shear, potentially improving seeding efficiency (Frauenschuh, et al., 2007). However, this approach can lead to poorer cell distribution and increased aggregation onset early in the bioprocess, requiring optimisation. CellRev’s media additive, AggreGuard™, can significantly reduce aggregate formation observed after intermittent seeding.

3) Operational Challenges and Considerations

Controlling pH and dissolved oxygen (DO) in stirred tank reactors

Unlike spinner flasks, stirred tank reactors employ control loops for precise pH and dissolved oxygen (DO) management, often without relying on atmospheric blanketing. These methods offer greater control compared to spinner flasks (Derakhti, et al., 2019). Common, cost-effective practices include:

i) pH control:

- Bicarbonate-based buffering system.

- CO2 addition for lowering pH, making the system more acidic.

- Base for raising pH, making the system more alkaline.

ii) DO control:

- Filtered air or pure oxygen addition. This will be dependent on the cell type and can sometimes require nitrogen sparging for cells which require hypoxic conditions.

Control loops introduce additional considerations, particularly during cell seeding, where aeration can negatively impact the process. Aeration mitigation strategies can include:

- Reduced Seeding Volume: A smaller culture volume enhances oxygen transfer, potentially eliminating the need for air addition.

- Atmospheric Blanketing or Novel Sparging Strategies: If reduced volume approaches don’t provide enough oxygen mass transfer, consider atmospheric blanketing or specialised sparging techniques to maintain oxygen levels without compromising seeding.

- Weak Acid for Seeding pH Control: A weak acid, such as Sodium Acetate, can temporarily replace CO2 sparging for pH control during seeding.

- Use a Different Buffer: HEPES and other Good’s buffers are independent of CO2 concentration but come with their own considerations.

- Predicting pH Extremes: For low cell numbers, anticipate a pH rise during seeding due to CO2 outgassing. Start seeding at the lower end of the desired pH range and monitor its natural rise. Conversely, with high cell numbers, expect lactate production to quickly lower pH. Begin seeding at the higher end of the range and monitor the natural decrease.

Large Media Addition and Potential Spikes

A critical moment occurs when the culture volume is adjusted to operational levels after seeding. This often involves a significant volume increase (e.g., 500mL to 2L), potentially introducing challenges:

- Oxygen Spike: Fresh media, often saturated with oxygen, can cause a temporary spike in DO concentration followed by a quick reduction in oxygen concentration (due the reduced oxygen diffusion efficiency). Ensure the DO control loop is activated during this phase to maintain the DO setpoint.

- pH Spike: Media prepared and stored can have a slightly higher pH than physiological. Adding this can cause a sudden pH rise, triggering excessive CO2 addition and harming the cells with excessive gassing. Always strive to add media pre-equilibrated to the operational pH and temperature.

These considerations ensure optimal control of pH and DO during cell seeding and culture expansion in stirred tank reactors.

Author: Travis Kemp, Bioprocessing Engineer at CellRev

References

Chang, H.-I. & Wang, Y., 2010. Cell Responses to Surface and Architecture of Tissue Engineering Scaffolds. Regenerative Medicine and Tissue Engineering – Cells and Biomaterials.

Derakhti, S., Hamid Safiabadi-Tali, S., Amoabediny, G. & Sheikhpour, M., 2019. Attachment and detachment strategies in microcarrier-based cell culture technology: A comprehensive review. MAterials Science & Engineering C, 103(109782).

Frauenschuh, S. et al., 2007. A Microcarrier-Based Cultivation System for Expansion of Primary Mesenchymal Stem Cells. Biotechnology Progress, 23(1), pp. 187-193.

Martin, C. et al., 2017. Revisiting MSC expansion from critical quality attributes to critical culture process parameters. Process Biochemistry, 59(Part B), pp. 231-243.

Meng, J. et al., 2017. Cell adhesive spectra along surface wettability gradient from superhydrophilicity to superhydrophobicity. Science China Chemistry, Volume 60, pp. 614-620.

Ng, Y.-C., Berry, J. & Butler, M., 1996. Optimization of physical parameters for cell attachment and growth on macroporous microcarriers. Biotechnology and Bioengineering, 50(6), pp. 627-635.