App Notes: AggreGuard & Kuraray Scapova CL PVA Microcarriers

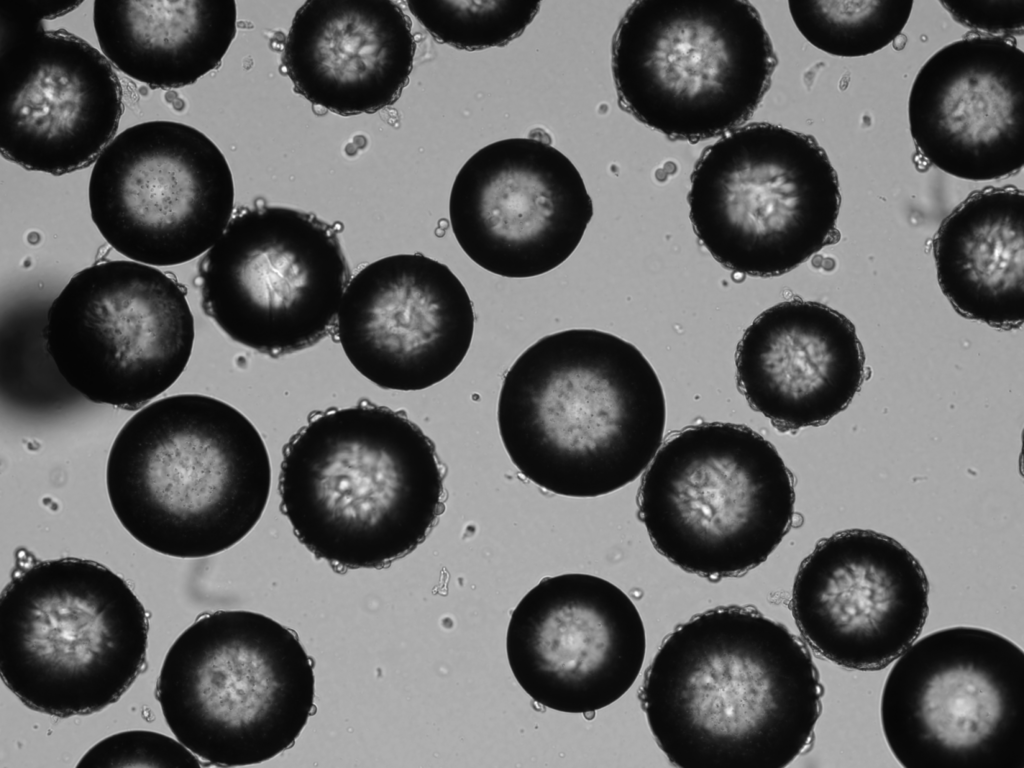

We assess the impact of our media additive, AggreGuard, on cell-to-cell mediated microcarrier aggregation for VERO cells grown on Kuraray’s Scapova CL PVA microcarriers. Designed to increase cell viability and eliminate processing bottlenecks, AggreGuard controls and reduces cell-to-cell attachment without affecting cell-to-surface attachment. In this study, we put AggreGuard to the test to determine its …

App Notes: AggreGuard & Kuraray Scapova CL PVA Microcarriers Read More »