Welcome to the Table

Enzymes are nature’s quiet overachievers, and at CellRev, we’re giving them a seat at the head of the bioprocessing table. This blog explores how our enzymes are transforming cell culture workflows from sticky messes to smooth, scalable systems.

Here’s your three-course tasting menu.

Starter: The Age-Old Alchemy of Enzymes

From cheese to cell therapy, nature’s catalysts get a precision upgrade

Enzymes have been doing our dirty work since long before we understood them. Cheese? Beer? Bread? All powered by enzyme magic. But where humans once stumbled into using them, we now decode their functions with surgical clarity.

Today, more than 4,000 enzymes are known to drive key reactions in everything from food to fuel, textiles to therapeutics. They’re nature’s catalysts: elegant, efficient, and incredibly precise.

Why do we love them at CellRev? Because enzymes offer what most industrial processes don’t:

- Higher performance

- Lower waste

- Built-in biodegradability

They’re tunable (by dose, time, or temperature), and typically cleared during processing, meaning no unwanted guests in your final product.

Bottom line: enzymes make systems smarter. And we’re applying them where it counts: in upstream biopharma.

Main: Cutting the Clump. Boosting the Batch.

How AggreGuard™ unsticks the problem upstream

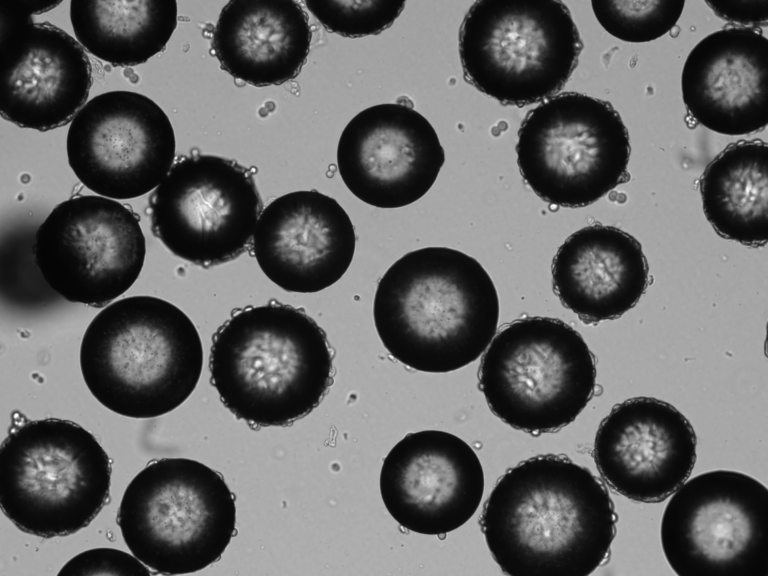

Let’s be honest: cells are clingy. Inside the body, they stick to form tissues. Outside the body, in vitro, that behaviour gets in the way.

Big clumps mean:

- Suffocated cells

- Inconsistent yields

- Wasted product

Enter AggreGuard™, our flagship enzyme.

It works like this: cells secrete a sticky substance called extracellular matrix (ECM). AggreGuard™ uses targeted proteases to gently break down ECM bridges, preventing aggregation without harming the cells themselves.

✅ Increased culture homogeneity

✅ Healthier, more productive cells

✅ Up to 75% viability boost

✅ 2–3x viral titre increases

✅ Smoother scale-up, fewer failed batches

It’s already validated across multiple cell types — from VERO to MSCs. And in viral vaccine production, the math is undeniable: same equipment, 3x more doses per year.

Curious what’s next? We’re exploring AggreGuard’s role in AAV manufacturing to reduce HEK cell aggregation. Let us know what you think.

Dessert: Sweet Release — Towards Continuous Manufacturing

Controlling when cells let go, and what it unlocks.

Sticky cells aren’t just a clumping problem. They also stick to surfaces. So what if you could tell cells exactly when to detach — and do it gently, reliably, and on repeat?

We’re working on that too.

Our second enzyme-in-development, currently codenamed Continuase, is designed to influence cell-to-surface adhesion. By fine-tuning ECM breakdown, we’re enabling controlled, continuous detachment.

Initial results show that Continuase supports the continuous culture of adherent cells across different systems:

- Flat plates

- Microcarriers

- 3D aggregates

Our proof-of-concept work in hiPSC aggregates inside stirred tank reactors is especially promising.

Enzymes have always been powerful. Now they’re precise.

At CellRev, we’re harnessing their potential to solve the biggest upstream challenges in biopharma. From preventing clumping to enabling continuous manufacturing, our enzyme cocktails are designed to make processes cleaner, smarter, and more scalable.

Ready to taste what’s next? Drop us a line.