In the race to make vaccines faster, cheaper, and more equitably distributed, one challenge has quietly dragged behind the spotlight: upstream bioprocess inefficiencies.

These early-stage production bottlenecks are where promising vaccine candidates either scale into commercial success or fizzle into sunk costs. And yet, despite their impact, upstream processes are often treated as rigid frameworks—something to work around, not rethink.

At CellRev, we believe that’s a mistake. Our recent case study on AggreGuard™ shows why fixing the upstream isn’t just technically feasible – it might be the highest-leverage move the vaccine industry can make.

The Clumping Conundrum

Let’s start with a problem almost everyone in cell-based biomanufacturing knows too well: clumping.

In suspension cultures, particularly those using microcarriers (MCs), mammalian cells tend to clump together via a biological mechanism called cell-to-cell adhesion (C2CA). It’s an evolutionary feature: cells are designed to physically interact and form tissues, with the extracellular matrix (ECM) serving as their scaffolding and shield.

But what makes tissue formation possible makes cell-based biomanufacturing an exercise in frustration. These aggregates limit mass transfer, reduce cell viability, increase batch heterogeneity, and ultimately lead to lower yields and higher costs.

Worse still, the industry’s current solutions to C2CA—like using high agitation, media reformulation, or cell line engineering—are time-consuming, expensive, and often incompatible with scale.

A Gentle Disruption: How AggreGuard™ Works

AggreGuard™ offers a smarter solution: target the ECM, not the cells. By using a blend of enzymes designed to gently act on the components that mediate C2CA, AggreGuard™ prevents aggregation without compromising cell health or productivity. It’s a controlled, reversible, and highly tunable approach that works with, not against, cells’ biology.

In a recent study, we tested this hypothesis using Vero cells cultured on Sartorius SoloHill® Plastic Plus microcarriers in 125 mL Corning spinner flasks. We simulated a viral infection using an AAV vector expressing eGFP (a fluorescent marker protein) to observe productivity outcomes with and without AggreGuard™.

The results? Nothing short of compelling.

3X Productivity Without Process Overhauls

By enzymatically controlling C2CA with AggreGuard™, we saw:

- ~3-fold increase in eGFP production, as quantified by fluorescence intensity normalised to protein content.

- Up to 2X higher viable cell yield at the end of the process.

- Sustained peak productivity over multiple days, unlike the steep drop-off observed in control cultures.

- Significantly improved culture homogeneity, with reduced cell debris and no visible aggregation by the end of the run.

These gains didn’t require changing media, redesigning hardware, or re-engineering cells. Just one carefully timed addition of AggreGuard™ on day 3 of the process.

Death by Clumping (Literally)

Why do these improvements matter?

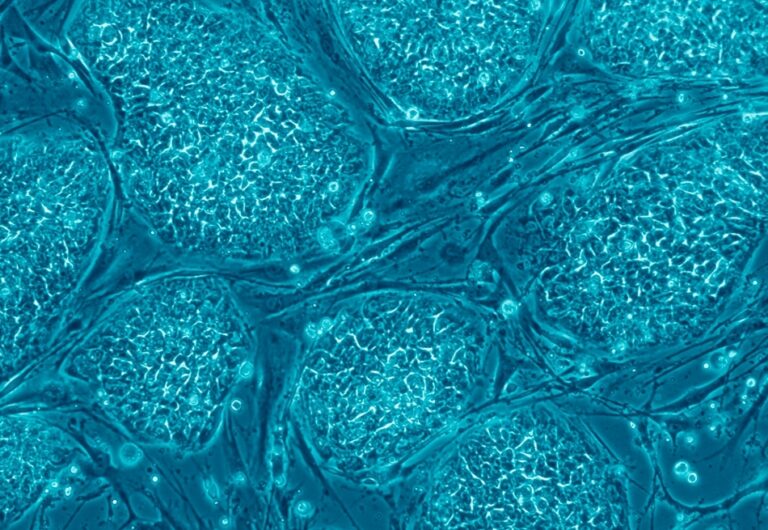

Because cell clumping doesn’t just hinder productivity – it kills cells. As shown in our live/dead staining and brightfield micrographs, aggregated cultures experience significant cell death, particularly in the dense regions between clumped microcarriers. This isn’t just about space, it’s about nutrient and waste exchange.

Clumped cells do not have access to nutrients and gases, triggering stress responses, impaired growth, followed by cell death pathways, especially in the presence of transduction agents like AAVs or fluorescent proteins like eGFP, which can induce oxidative stress.

AggreGuard™ mitigates all of this by maintaining a healthier culture environment throughout.

Why Upstream Matters More Than You Think

In many vaccine bioprocesses, upstream development accounts for ~30% of total manufacturing costs. But inefficiencies in this phase ripple downstream through purification challenges, variability in yield, and process validation complexity.

Most importantly, they determine whether a candidate even makes it through tech transfer and scale-up. As vaccine demand rises globally—especially for LMICs and pandemic preparedness—scalable, efficient upstream solutions are no longer optional.

They’re strategic.

Conclusion: Fix the Foundation, Free the Future

The path from lab bench to end product is complex, fragile, and high-stakes. But if we want faster, fairer vaccine access around the world, we must start by fixing the foundations, starting with upstream cell culture.

AggreGuard™ is not just a tool; it’s a rethink of how we approach upstream inefficiency: not as an unavoidable compromise, but as a solvable design problem. By controlling clumping at the source, we give manufacturers better yields, better consistency, and better economics, all without disrupting what already works.

Because sometimes the smartest innovation is the one that quietly makes everything else easier.