In the shadow of pandemics, resurging viruses, and global vaccine inequality, the way we manufacture vaccines is more important than ever. Despite massive technological leaps in genetic sequencing, AI-assisted drug discovery, and cold-chain logistics, one fundamental aspect of vaccine production has stubbornly resisted progress: the way we grow the cells that produce them.

At CellRev, we believe we’ve solved a key piece of that puzzle with AggreGuard™—a first-in-class media additive designed to prevent mammalian cells from clumping together during manufacturing. It may sound like a minor challenge, but it could have major consequences for productivity, affordability, and global access to vaccines.

The Hidden Problem: Cell-to-Cell Adhesion (C2CA)

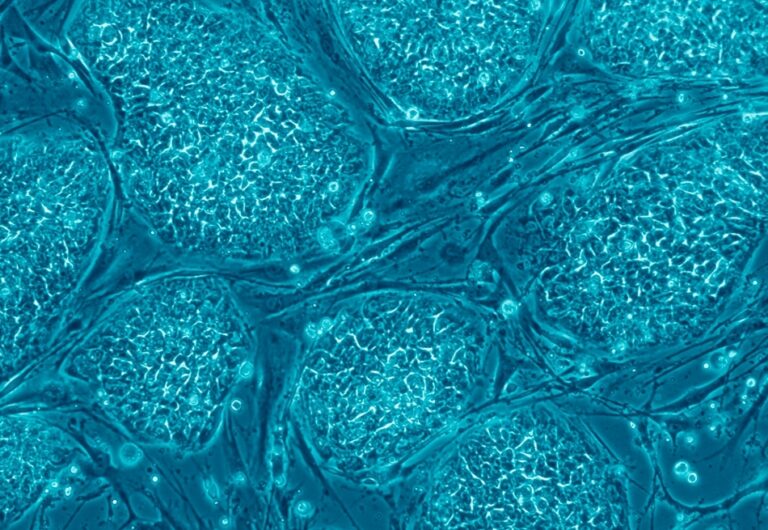

Viral vaccines are typically grown in bioreactors using mammalian cells such as Vero cells or fibroblasts. These cells are often cultivated on microcarriers floating in the nutrient-rich media in stirred tanks. This method, introduced to industry in the 1970s, allows a much larger surface area for cell growth compared to traditional flat surfaces, theoretically enabling higher viral yields per batch.

But there’s a catch.

As the cells grow, they tend to stick together—a phenomenon known as cell-to-cell adhesion (C2CA)—and this aggregation gets worse as scale increases. These clumps, or cell-microcarrier aggregates (CMAs), reduce the homogeneity of the culture, negatively impact cell health, and ultimately tank productivity. For manufacturers, that means higher batch failure rates (up to 70% in early-stage development), more expensive downstream purification, and skyrocketing costs of goods sold (COGS).

For years, the industry’s workaround has included the addition of harsh surfactants, costly genetic engineering approaches, or simply accepting batch loss. None of these is sustainable.

AggreGuard™: A Smart, Gentle Solution

CellRev’s AggreGuard™ offers a fundamentally different approach: instead of chemically forcing cells apart or engineering them to behave differently, AG uses a cocktail of naturally derived bacterial enzymes to selectively digest components of the extracellular matrix—the biological “glue” that causes C2CA.

Critically, AggreGuard™ does this without harming the cells or impeding their productivity. Our data on Vero cells—the workhorse of viral vaccine manufacturing— showed AggreGuard™ improved viral yield by up to 2.3-fold and showed no cytotoxicity even after 60 days of continuous exposure. We already showed it works with major microcarrier brands (Corning, Cytiva, Sartorius), is stable in physiological conditions, and is available in both research and GMP-grade formats.

In other words, it’s plug-and-play for most vaccine production systems, and that matters.

Why It Matters to Global Vaccine Supply

Here’s the bigger picture. The vaccine market is projected to hit $86 billion by 2032, driven by growing populations, disease resurgence (like measles and polio), and new pathogens. Yet global manufacturing capacity still lags behind. The bioprocessing industry must scale production by 20-fold to meet expected needs, with over 1,000 new manufacturing sites required globally by 2030.

At the same time, most of the world’s vaccine supply is still based on decades-old manufacturing models. Many of these processes are inefficient, expensive, and difficult to transfer, especially to low- and middle-income countries where vaccination rates are dangerously low. This is not just a technical bottleneck—it’s a moral one.

AggreGuard™ directly addresses one of the biggest causes of inefficiency: batch loss and low bioreactor productivity caused by clumping. By reducing aggregation, AggreGuard™ improves yield and helps maintain the health and homogeneity of cultures. The result? Fewer lost batches, better scalability, and lower costs per dose. An estimated 15% gain in process efficiency can reduce COGS by as much as 20%.

That could make the difference between a $6 vaccine and a $2 vaccine. Multiply that by hundreds of millions of doses, and the public health implications are enormous.

A Game-Changer for Legacy and Emerging Vaccines

While the technology has immediate relevance for classic viral vaccines like MMR (measles, mumps, rubella), polio, and rabies, it’s equally transformative for newer platforms. Pandemic preparedness efforts demand flexible, scalable systems that can rapidly pivot to produce vaccines for unknown pathogens. That means manufacturing platforms must be more adaptable and robust than ever.

AggreGuard™ also opens the door for using more productive—but traditionally harder to handle—cell types like MRC-5 fibroblasts, which are halal-certified and acceptable in regions where Vero cells are not. This enables culturally inclusive vaccine production, an often-overlooked aspect of global health equity.

The Road Ahead: Partnerships and Global Rollout

CellRev is already working with a network of forward-thinking partners, and our collaboration with Austrian-based bespark*bio is producing a comprehensive dataset on AggreGuard’s effect on viral titre and scalability, critical for derisking adoption. We’re also building detection assays to satisfy regulatory requirements for downstream removal of enzyme residues.

And yes, the world is paying attention. From the UK-Southeast Asia Vaccine Hub to biotech conferences across Europe and Japan, AggreGuard™ is being welcomed as the kind of smart, enabling tech that can future-proof vaccine manufacturing without massive infrastructure changes.

**In summary:** Cell clumping might sound like a minor technical nuisance, but its impact ripples through the entire vaccine production process, slowing scale-up, increasing costs, and limiting access. With AggreGuard™, CellRev is not just solving a bioprocessing challenge – we’re helping clear a bottleneck that has global public health consequences.

In a world that desperately needs more vaccines, faster, and for everyone, that’s a mission worth rallying around.