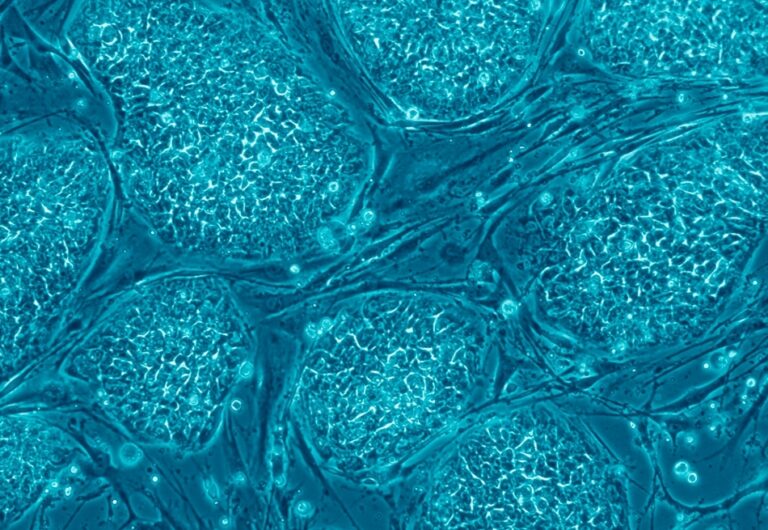

CellRev has developed a revolutionary new approach to adherent cell culture, promising to transform the commercial potential of this nascent field.

The company spun out of Newcastle University in 2019, where the foundations of its tech breakthrough first began. As a pioneering new company, CellRev’s innovation brings immense commercial potential, helping to match growing demand and meet future needs.

How did CellRev discover its breakthrough technology?

CellRev traces its earliest origins to Newcastle University in 2015. While completing her PhD in Corneal Tissue Engineering, co-founder Dr Martina Miotto discovered that with the right additive in the system, cells that were adherent to a surface could continue to proliferate and detach in a controlled manner.

This breakthrough forms the basis of CellRev’s technology.

Inspired by its potential, Martina was encouraged to continue ongoing lab research by CellRev co-founder Che Connon, Professor of Tissue Engineering and Director of Business Development at Newcastle University.

2017 marked another exciting step. that highlighted CellRev’s ability to match growth and detachment rates to achieve a steady state. This finding paved the way for the transition into continuous bioprocessing.

Continuous cell manufacturing is an exciting move away from the surface area limitations of its counterpart batch processing. While continuous processing is not new, the process CellRev has developed is a crucial shift towards a pioneering and scalable method of expanding cells.

Drawing on the findings of Martina’s early research, the CellRev continuous process has been refined, ensuring an efficiency that can be replicated to scale for many industries and applications.

Unlocking CellRev’s commercial potential

CellRev unlocks the commercial viability of adherent cell culture.

The process can be explained in four steps:

- Establishing the correct parameters in the lab, ensuring output is optimised to meet the client’s needs.

- Seeding the bioreactor and growing cells to 80% confluence leaves space for further cell growth.

- Detaching cells with the use of CellRev’s proprietary cell detachment system triggers the release of cells from surfaces.

- Continuously harvesting biomass for downstream processing.

The established protocol can be repeated as required on each new production run.

This industry-first technology has the potential to help solve the scalability and affordability challenges of adherent cell culture. CellRev has effectively combined both cell expansion and collection into one efficient upstream production process, presenting significant benefits to the end consumer.

At the outset of forming CellRev as a company, the team knew they had to first explore routes to commercialise the technology, assessing demand as well as practical need.

This involved both investigating and outlining the compelling commercial potential of CellRev technology:

- Martina carried out primary research around the globe, to better understand potential customer pain points and how the tech could help solve them.

- Martina and Che attended workshops, built business plans, and worked to secure funding for the continued development of this exciting new company.

- CellRev sought funding from the private sector, with Che drawing on his considerable experience as a company founder.

The company’s funding was secured from Innovate UK, with additional investment from local investor NorthStar Ventures, who continue to support the business to this day.

The future of CellRev technology

CellRev’s technology has multiple real-world applications that could revolutionise numerous industries, including cellular agriculture and biopharma. Cellular agriculture is expected to become a booming industry in the years ahead, and CellRev’s tech will have a measurable impact on the scalability of cell manufacturing.

As demand grows, the need for safe, efficient, continuous adherent cell culture is also set to rise. Yet the development of solutions has been slow, unable to keep up with both the rising level of interest and the forecasted future demand.

The CellRev team continues to test the technology’s compatibility across different cell types, and report on the results.

With a growing global population to feed and concerns over the negative impact of conventional production processes, CellRev’s technology presents a real, cruelty-free, and inherently scalable alternative to traditional meat production.

The same technological breakthrough could help patients receive the care they need, providing access to life-saving treatments.

To find out more and discuss your unique requirements with the CellRev team, get in touch.