Continuous processing is not new and is being adopted by more and more industries as they acknowledge the inherent limitations of batch processing.

However, CellRev’s technology offers a revolutionary new approach to cell manufacturing.

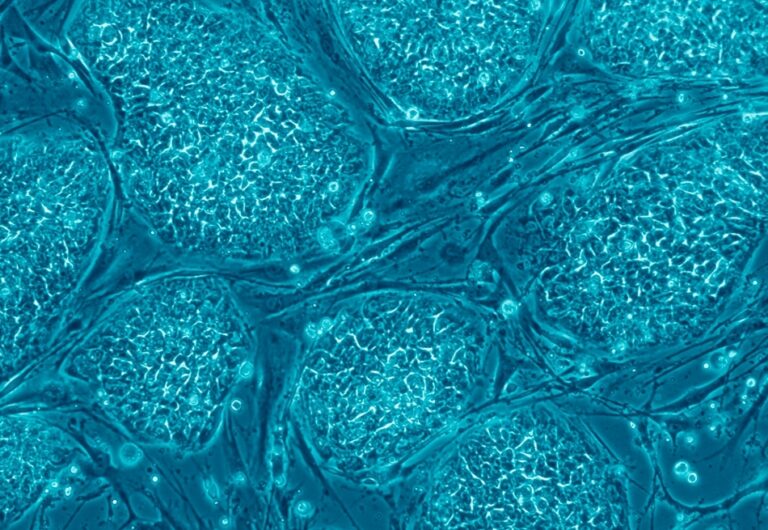

What is an adherent cell?

There are two primary systems used for culturing cells: adherent cell culture and suspension cell culture. There are benefits and challenges to each process. Yet adherent cell culture is usable for most cell types, making it a preferable option in many instances.

Suspension cells effectively grow as they ‘float’ in their suspension media, whilst adherent cells need to be attached to a surface to grow.

CellRev technology works with adherent cells. In a commercial setting, the key challenges around adherent cell culture have traditionally included scalability, affordability, efficiency, and quality control – each of which CellRev addresses with its pioneering tech.

Designed to scale

Adherent cell culture has been used for small-scale projects quite frequently, but scalability has always presented a big challenge. This has in turn blocked this form of cell culture from achieving its true commercial potential.

When projects need to expand large collections of cells, it is inconvenient to be restricted by surface area (as cells must be adherent to a surface), and an inability to successfully and efficiently detach and harvest cells has resulted in numerous processing challenges.

In this context, it is understandable that the rate of innovation has previously been slow.

CellRev’s continuous process is inherently scalable. Free from the restrictions of batch processing and combined with the ability to control detachment rates, scalability and commercial rollout are now within easy reach.

An affordable option

Affordability has been another barrier to commercialising adherent cell culture.

The end product is expensive. High operating costs and significant capital expenditure are both required to increase capacity, which serves to further inhibit scalability.

Large processing sites can be heavy on budgets. When adopted at a commercial scale, cell culture can take up considerable physical space, calling for the use of more land, more labs, and more resources. This added complication and cost are no longer necessary.

CellRev has made adherent cell culture more affordable by significantly reducing operating costs and CAPEX (capital expenditure) at scale.

A more efficient process

Efficiency is yet another barrier to commercial cell culture at scale.

When compared to the restrictions of batch processing, the CellRev system is significantly more efficient and can improve the overall production yield by as much as 3x.

As the CellRev process is continuous, there is no need to stop, harvest cells and clean the system. The bioreactor can be held at higher confluency and run for extended periods of time, resulting in a much higher output within the same time period as a batch process.

A quality-controlled system

The clear and efficient process that fuels CellRev not only leads to higher-quality output but more stringent quality control procedures at every stage. This is a vital step for commercial application, ensuring rigorous standards are upheld.

Sophisticated monitoring and feed systems are integrated into CellRev to help facilitate extended running times.

The technology lends itself to automation, removing errors due to human interaction and manual handling, and boosting quality control at every level.

How can CellRev help with my project?

CellRev’s bioprocess can be used to help facilitate a shift from batch to continuous processing, increasing existing manufacturing output. Likewise, the technology can be adopted at the very start of development to safeguard an increased return on investment.

The company is constantly testing new cell types to assess compatibility and report on the results. CellRev’s system offers a scalable, quality-controlled, efficient, and affordable process that makes adherent cell culture a viable commercial option for everything from cultured meat and seafood to innovative cell and gene therapies.

To find out more about how the technology could help you, contact the CellRev team.